Fish oil makes for a safer, greener form of plastic

This fish-oil-based polyurethane may help clear the way for greener plastics.

Canadian chemists have invented a way to turn fish oil into a cleaner form of polyurethane — one that doesn't stink — which they hope will help open up a viable market for safer, more environmentally friendly plastics.

Mikhailey Wheeler, a chemistry master's student at Memorial University of Newfoundland, will present an abstract of the team's preliminary research on biodegradable fish-oil-based polyurethanes April 8 at ACS Spring 2021, an American Chemistry Society meeting.

Polyurethane is a versatile type of plastic that has a range of common applications. In its rigid or flexible forms, polyurethane appears in foams, adhesives, clothing and appliances, as well as in food packaging and a variety of other items. Typical polyurethanes derived from crude oil are toxic at almost every level of production.

Prior studies have examined the viability of other nontoxic substances in safer polyurethane production, and researchers from Purdue University have made advances with water-based polyurethanes. While it is also possible to create these polymers from linseed and soybean oils, the team behind the fish-oil-based plastic did not want to depend on oil that could be used in food.

Instead, being close to the eastern Canadian coastline, the researchers looked to the ocean and realized they could try sourcing oil from the salmon guts and capelin herring discarded by fisheries every day.

"It's like two birds, one stone: You make the polyurethanes better, but you're also making the aquaculture industry better," Wheeler said in an interview with The Academic Times.

To make polyurethanes, polyols and isocyanates are first derived from crude oil. These compounds then react with one another to create a polymer. Isocyanates are particularly toxic because they are made using phosgene gas, which was used by armies during World War I as a "choking agent." Outside of war, exposure to phosgene gas can cause shortness of breath, nausea and pulmonary edema.

Wheeler and her colleagues improved the environmental safety of this process by replacing isocyanates with fish oil and using a cashew-based amine to set off the chemical reaction that helps form the plastic.

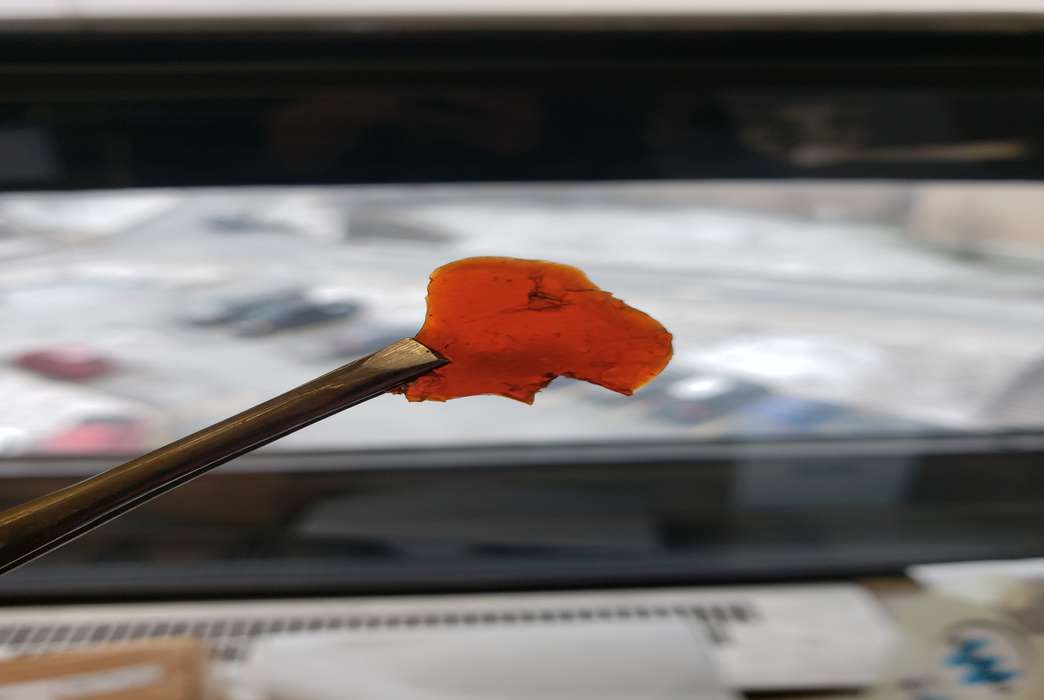

During this chemical treatment, the oil becomes slightly less viscous before it's placed in a petri dish, and then into an oven at 100 degrees Celsius. After baking, the resulting polymer is a soft, flexible plastic that is a deep shade of red. This technique can produce up to 2 grams of plastic per 1 gram of fish oil.

After helping develop this polymer with a cashew-based amine, Wheeler and some of her colleagues have tried to improve on the original formula by using an amino acid instead of the cashew-based amine, which may be slightly toxic.

Still, Wheeler and her colleagues have reason to believe that they have a safer polyurethane on their hands. Where most plastics take many years to degrade, this fish-oil polyurethane appears to start degrading in as little as two weeks. In one experiment, Wheeler saw mold forming on one of her samples during an experiment after leaving it in solution for about one month.

"There was just fuzzy stuff everywhere," Wheeler said. "And that was pretty surprising, so that was a good thing."

As of now, this fish-oil polyurethane still needs to undergo a number of tensile-strength tests before Wheeler and her colleagues consider any partnerships with potential buyers. They also want to scale up production of the formula that uses an amino acid, such as asparagine or glutamine. Right now, this formula is operating on only a milligram scale, whereas the cashew-based amine formula is being studied at a gram scale.

And while they have some indication that the material is biodegradable, they still want to answer more questions to study its environmental impact. Until then, Wheeler and her colleagues remain open to partnerships to source more fish oil. They need a lot of it.

The abstract, "Waste Fish Oil for the Production of Greener Polyurethane Materials," to be presented April 8 at ACS Spring 2021, was authored by Mikhailey D. Wheeler, Courtney M. Laprise, Christopher M. Kozak and Francesca M. Kerton, Memorial University of Newfoundland.